Weighing ingredients in the chemical industry

Release Time:

Jan 22,2019

Application 1. Chemical products In the production process, different raw materials, according to their specific production processes and process equipment, through the automatic monitoring and control of temperature, pressure, flow, batching accuracy and other production parameters, to achieve a stable product quality.

Application 1. Chemical products In the production process, different raw materials, according to their specific production processes and process equipment, through the automatic monitoring and control of temperature, pressure, flow, batching accuracy and other production parameters, to achieve a stable product quality. After quality inspection such as particle size, moisture, and viscosity, it is stored and transported in a specific temperature, seal, etc. environment. Due to the complexity of raw material properties, powders and granular solids have differences in fluidity, moisture absorption, and corrosivity, and liquids are also flammable, explosive, and volatile. Therefore, combined with the characteristics of different chemical processes, through the integration of weighing sensors, computers, PLC and other equipment for weighing automation technology, enterprise ERP information transformation and upgrade, can better help chemical companies to ease workers' labor pressure, improve and Improve product quality, effectively manage raw materials and production consumption; and by reducing production costs, highlighting product advantages, and improving production efficiency, the competitiveness and industrialization level of chemical companies will be greatly enhanced.

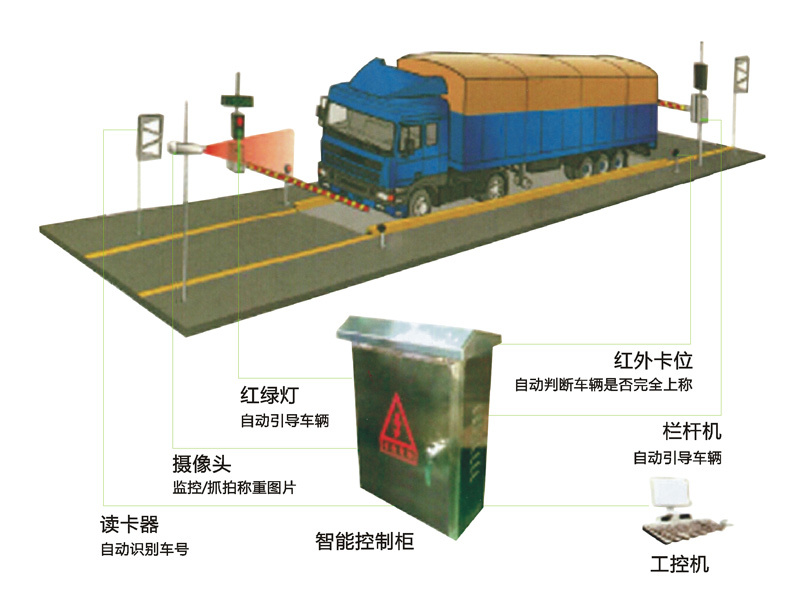

Application 2. Automation system of chemical industry With the improvement of automation level and information management level of chemical enterprises, especially the strict requirements of precision production, batching precision, product quality and control level, in order to cooperate with the control function of complex automatic weighing control system Automation systems/software are widely used for implementation, as well as the need for centralized management of different production equipment and statistical analysis of multi-batch production data. Depending on the automation of the production environment and the need for human involvement, the entire system includes an automated computer control system and a weight data acquisition system.

The weighing system establishes a perfect connection network with the field devices, so that the collection and control of the production parameters such as weight, temperature and flow on the site are concentrated in the central control room. It is suitable for the upgrading of production lines in fast-paced, high-yield production mode. With the help of PLC and other equipment, it can reduce labor costs, improve production efficiency, and stabilize and operate reliably under the requirements of refined production. Although the initial investment is large, the return benefit is obvious. Its features include: (1) using the fieldbus protocol to configure each collection point, with high-speed real-time communication function and data remote transmission function; (2) the networked system can receive scheduling production orders, laboratory recipe instructions, and can upload data with ERP network; (3) It has a formula library and database management function, and the report statistics function can provide query and print according to time (shift, day, month), raw material consumption, output, etc. In addition, the system can interact with other management systems to meet deep data analysis requirements.

Related News