How to judge the fault of electronic platform scale sensor

Release Time:

Jan 03,2019

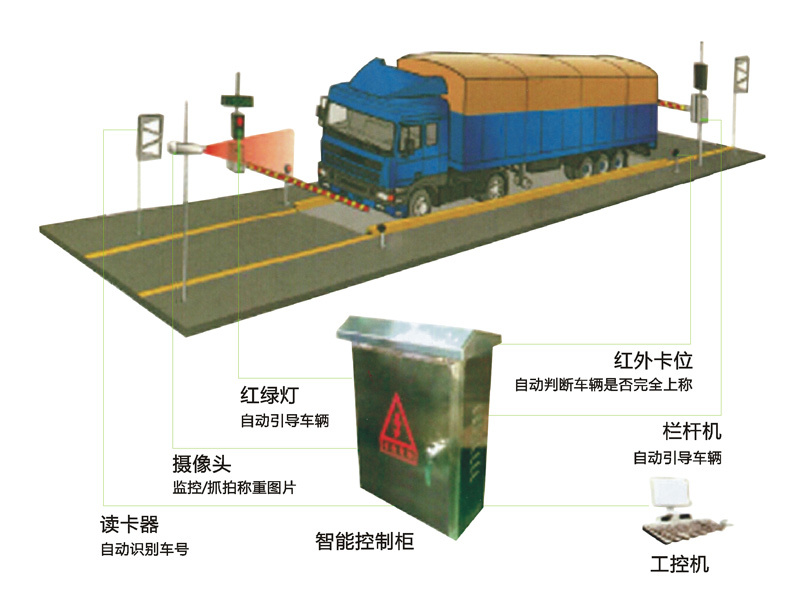

Monitoring of the empty scale of the electronic platform scale sensor. Under the condition of actual weighing condition, the carrier body (or the bearing frame) is placed, and the mechanical parts are also in place.

How to judge the error of the electronic platform scale sensor

1. Monitoring

(1) Monitoring of the empty scale of the electronic platform scale sensor. Under the condition of actual weighing condition, the carrier body (or the bearing frame) is placed, and the mechanical parts are also in place. Measure the output value of each sensor of the scale under the excitation voltage, and edit the number according to the position to make a record. This is the output value of the sensor empty scale.

(2) Monitoring of the no-load of the electronic platform scale sensor. Under the actual weighing condition, each sensor of the scale is placed in the no-load state, and the output value of each sensor under the excitation voltage is measured, and the number is compiled according to the position, and the record is made, which is the no-load of the sensor. output value. At the same time, the input impedance of the sensor is measured, and the output impedance is compared with the no-load output with the technical specifications given by the manufacturer at the factory.

(3) After loading the standard weight with the standard weight, it is better to measure the output value of each sensor of the scale under the standard weight loading condition, make the number according to the position, make a record, and indicate the standard weight value. This is the sensor weight output value.

2, tracking

According to the location, occasion, environment and other conditions to determine the time interval of the next measurement, the empty scale output (or standard output) and no-load output of each electronic scale sensor are tracked and measured.

(1) Using the production gap, periodically measure the empty scale output and the no-load output of each sensor of the scale, and conditionally measure the output of each sensor under the same standard weight. Make a record and compare it with the original record.

(2) When the sensor's empty scale output (or standard weight output) and no-load output change greatly, the tracking time gap should be shortened, and the tracking density should be increased; when the output is stable for a long time, the tracking gap can be extended appropriately. .

(3) The same load is compared at different points (segments) of the scale, and the difference is measured. The empty scale output and the no-load output of each sensor are measured, and the record is made and compared with the original record. This method is commonly used in the production of fast-paced weighing conditions to understand the operation of the scale.

(4) When presenting the phenomenon of "sub-health" of the electronic platform scale sensor, it is necessary to increase the measurement density of the empty scale output (or the standard output) of each sensor to track the empty load output, make a record, and compare with the original record. .

(5) For the digital sensor, use the same method to monitor and track the internal code value of the empty scale, the no-load internal code value, and the internal code value of the standard weight, and make a record.

3, analysis and diagnosis

According to the comparison, we must carefully analyze the weighing conditions and go to the pseudo-seeking truth. Targeted inspection of the status of on-site mechanical components (clip, etc.) to determine whether it is a mechanical problem or other problem. It is a mechanical problem to be corrected in time. The sensor "sub-health" tends to be accompanied by certain phenomena. It is necessary to grasp the data measured at this time, as the node of analysis, to find and confirm the intrinsic law in the comparison, and to form a diagnostic after repeated verification. Indicators to guide future maintenance work. The type of each sensor and the weighing conditions are different. The size of the indicator reflecting the "sub-health" condition is also when the weighing of an electronic platform scale is inaccurate. There are many reasons we can think of, electronic A scale sensor fault is one of them. We want to repair the electronic platform scale, we need to first determine whether the electronic platform scale sensor is really faulty. Below, Shanghai Zhuheng Xiaobian will introduce you to the electronic platform scale sensor fault judgment method. I hope everyone can see something to gain. Not the same.

Related News